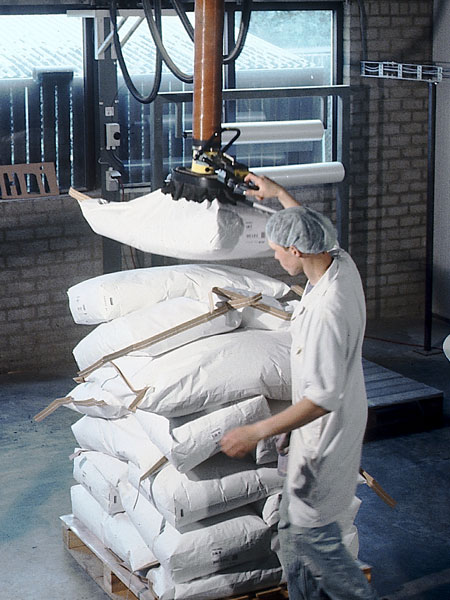

What is a Vacuum Lifter?

A vacuum lifter is a device the leverages the power of vacuum to help operators lift, move, or orient materials in a safe and efficient manner.

Both the vertical motion and gripping force of common vacuum lifters are generated by a single vacuum generation system. Different types of gripping mechanisms can be employed to engage product depending on the type of product and handling requirements. Vacuum lifters can be built in stainless steel and of sanitary / FDA approved components as well.

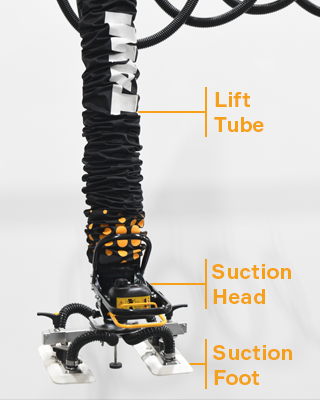

Suction Feet

This is the part of the device that comes into contact with the item to be lifted. Suction feet are infinitely configurable based on the size / shape / material of the item to be lifted. Suction feet are interchangeable via a quick-disconnect mechanism for fast application changeover.

Suction Head

This is the human interface of the vacuum lifter and how the operator controls the movement of material. Lifting handles can be one hand or two hand operated and can have different levels of customization depending on the form of the item to be handled.

Lift Tube

The lift tube is the vertical load bearing component and expands or contracts based on the vacuum pressure in the tube. Releasing pressure at the lifting handle lowers or releases the material whereas higher vacuum pressure grasps or raises the material. The type and size of lift tube employed is dictated by the desired lifting capacity of the system. For example, heavier lifting capacities require larger diameter lift tubes whereas lower capacities require less vacuum flow and thus, a smaller lift tube.

Structural Support System (Crane)

All vacuum lifters require a structural support system. The type of support relies on the desired application or space constraints within a given facility. Common structures include bridge cranes, jib cranes, portable jib cranes, and even specialized mobile order pickers which can attach to a forklift or fork truck. Cranes can be freestanding or integrated into an existing roof truss or column in a given building.

Vacuum Pump

Each vacuum lifter is powered by a single vacuum pump. This is similar in size and shape as a small air compressor and can be enclosed in a sound dampening device to lower the ambient decibel level in your facility. Along with the vacuum generator, hoses and connections are used to deliver suction at the point of use.

Contact Us